Journal Information

Title: Enfoque UTE

Editor-in-Chief: Diego Guffanti

Associate Editor: Miriam Recalde

Copyright: 2025, The Authors

Volume: 16 Issue: 3

ISSN (electronic): 1390-6542

Copyright statement: License (open-access,

https://creativecommons.org/licenses/by/4.0/)

Article Information

Date received: FEBRUARY 26, 2025

Date accepted: MAY 21, 2025

Publication date: JULY 1, 2025

Date of current version: JULY 1, 2025

Publisher: Universidad UTE (Quito, Ecuador)

Pages: 37-43

DOI: https://doi.org/10.29019/enfoqueute.1144

http://ingenieria.ute.edu.ec/enfoqueute/

Use of carbon activated impregnated with Fe to enhance methane production of wastewater from nixtamalization process

Vianey A. Burboa Charis1, Margarita S. Escalante Torres2, Miguel A. Armenta Gutiérrez3, Lourdes M. Tenorio Diaz4, Luis A. Leyva Soto5, Angel R. Meza6, Luis H. Álvarez Valencia7*

Abstract

Wastewater from the nixtamalization process represents a challenge due to its complex and highly alkaline composition. The present work aims to enhance methane production by anaerobic digestion of nejayote with conductive materials based on carbon modified with iron. Through two experimental phases, the most significant results show that the metal load in granular activated carbon (GAC) does not stimulate electron transfer in a medium such as nejayote. On the other hand, when the pH is kept at neutral values, an 88 % reduction in COD and high values of accumulated methane are obtained. The study describes the relationship between using GAC and nejayote as a methane promoter in anaerobic digestion, which can be a sustainable alternative.

Keywords

Anaerobic digestion, wastewater, nejayote, methane production, conductive materials, direct interspecies electron transfer (DIET).

Resumen

Las aguas residuales provenientes del proceso de nixtamalización representan un reto por su composición compleja y altamente alcalina. El presente trabajo tiene como objetivo potenciar la producción de metano mediante la digestión anaeróbica de nejayote con materiales conductores a base de carbón modificado con hierro. A través de dos fases experimentales, los resultados más significativos muestran que la carga metálica en el carbón activado granular (CAG) no estimula la transferencia de electrones en un medio como el nejayote. Por otro lado, cuando el pH se mantiene en valores neutros, se obtiene una reducción del 88 % en la DQO y altos valores de metano acumulado. El estudio describe la relación entre el uso del CAG y el nejayote como promotor de metano en la digestión anaeróbica, lo que puede ser una alternativa sustentable.

Palabras Clave

Digestión anaerobia, agua residual, nejayote, producción de metano, materiales conductores, transferencia directa de electrones entre especies (DIET).

I. INTRODUCTION

Corn is the crop that generates the most significant economic value in Mexico (seven largest producer worldwide) [1]. The tortilla is the main way of consuming corn in Mexico and is a fundamental part of its diet [2], the annual per capita tortilla consumption in urban areas is 56.7 kg, and in rural areas is 79.5 kg [3]. Most corn-based products are subjected to an alkaline treatment called nixtamalization, which allows them to increase their nutritional value [4]. Nixtamalization is a thermo-alkaline treatment that consists of cooking corn by adding calcium hydroxide, this preparation is cooked for 50 to 90 minutes and left to soak in the cooking water for 14 to 18 hours [5], [6]. This treatment helps to remove the pericarp from the grain, making amino acids (niacin and tryptophan) and minerals such as calcium more available; it also facilitates milling and improves the adhesiveness and extensibility of the dough produced [7]. After soaking, the cooking water known as “nejayote” is removed. Nejayote has an approximate composition of 92 - 94% water with a large amount of organic matter, and 6-8% solid corn residues, which include the pericarp, endosperm, germ, calcium and carotenoids, which give it its characteristic yellow pigmentation [6], [8]. It is estimated that a tortilla factory with a capacity of 600 tons of corn/day generates between 1500 and 2000 m3 of nejayote [9]. Nejayote is one of the most challenging effluents to treat because it is highly alkaline (pH>10) and has high concentrations of dissolved and suspended organic matter, with values of biological oxygen demand (BOD) between 7000 to 14 000 mg/L and Chemical oxygen demand (COD) in a range from 10 000 to 20 000 mg/L [10], [11]. Nejayote is rarely treated and is discharged directly into surface waters or public sewers [12]. This effluent generates turbidity and causes a reduction in dissolved oxygen, compromising the survival of various aquatic organisms. It also increases the content of nutrients (N and P), which contribute to the eutrophication process, leading to a significant environmental impact [11], [13].

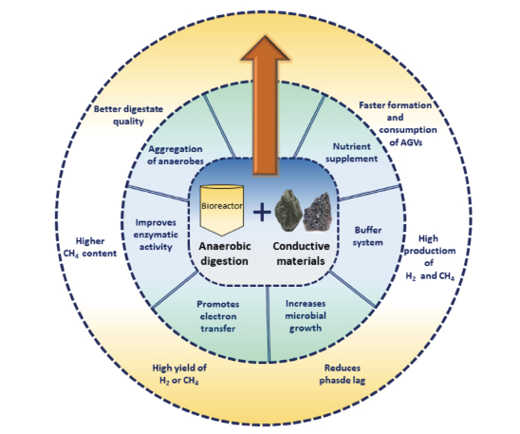

Aerobic water treatment systems are not considered an option due to the characteristics of nejayote; however, anaerobic digestion (AD) is a viable option for eliminating the organic load and producing biogas. AD is a four-stage biological process (hydrolysis, acidogenesis, acetogenesis, and methanogenesis); in the absence of oxygen, a mixed consortium of microorganisms transforms complex organic matter into its most oxidized (CO2) and most reduced (CH4) states [14]. The strategy through AD of generating clean energy from methane and biohydrogen has been explored [12], [15]. Currently, strategies have been established to improve the stages of AD, especially for complex compounds, and adequate electron transfer is required to increase the methane content in biogas. Direct electron transfer between species (DIET) is a syntrophic process that effectively promotes electron transfer in the anaerobic microbial consortium, being able to give up and accept electrons directly between species, promoting methane production during anaerobic digestion, in which they can involve electroactive bacteria, methanogens, anaerobic methane-oxidizing consortia, Geobacter species and co-cultures [10], [17]. Several studies have reported using electron-conducting materials, which improve the syntrophic relationships between fermentative bacteria and methanogenic archaea during methane production. Some processes in which conductive materials participate and promote during anaerobic digestion are shown in Fig. 1. In the last decade, carbon-based materials have been widely studied; in 2012, the use of iron oxide minerals was reported, obtaining favorable results, such as an increase in the maximum methane production rate and a significant reduction in the lag phase [18]. Adding carbon-based materials and metals is an option to improve methanogenesis during AD processes.

The main objective of this work is to treat wastewater from the nixtamalization process (nejayote) using carbon-based conductive materials, with and without iron, to enhance methane production. The objective was achieved through two experimental phases: 1) To evaluate the impact of different percentages of Fe in activated carbon to increase methane production during anaerobic digestion of nejayote; 2) To evaluate the production and composition of biogas by anaerobic digestion of nejayote, in a reactor with continuous stirring (CSTR) added with conductive material.

Fig. 1. Processes in which conductive materials participate and promote during anaerobic digestion and their impact on the productivity of methane and other products. Adapted from [19].

II. MATERIALS AND METHODS

A. Wastewater and inoculum

The nejayote wastewater was collected from a small corn tortilla factory that uses the nixtamalization process, located in Cd. Obregon, Mexico. The wastewater was sedimented for 24 hours, and pH and soluble chemical oxygen demand (CODs) were subsequently determined. The anaerobic granular sludge used for both experimental phases contained 16 % volatile suspended solids (VSS) in wet weight, collected from a large-scale UASB reactor of a local brewery, and dispersed to obtain a particle size of 425 µm. It was used as inoculum without prior acclimation to nejayote.

B. Conductive materials

Granular activated carbon (GAC) was used during the AD kinetics for methane production, which was produced from bituminous coal (Carbotecnia), was crushed and sieved to obtain particles between 150 and 250 μm; it was subsequently washed with distilled water to remove fine particles and dried at 55 ºC for 24 h. The modification of the GAC was carried out by an impregnation method [20], with Fe doses of 0.25, 0.5, and 1 %, in a solution of iron nitrate (Fe (NO3)3 9H2O) (Sigma-Aldrich) by weight according to Equation 1:

(1)

A is the metal used, MWA is the molecular weight of the metal, MWB is the molecular weight of the precursor metal, and C is the mass of the supporting material. The impregnation was carried out with 10 g of GAC with the iron nitrate solutions at 80 °C for 8 h at neutral pH, then the water present in each solution was evaporated at 110 °C for 12 h and finally thermally activated at 350 °C for 4 h with a temperature ramp of 10 °C/min.

C. Methane production kinetics with nejayote

The first experimental phase was carried out in 120 mL serological bottles, with 60 mL of nejayote operating volume. The initial CODs concentration was 15,688± 90 mg/L, inoculated with 1 g of SSV/L of anaerobic sludge. The bottles were sealed with rubber stoppers and aluminum caps, and then N2 was bubbled into the liquid to establish an anaerobic atmosphere. The incubations in triplicate were placed in an orbital shaker at 37 ºC and 130 rpm for 15 days. The liquid displacement method used a 2 % NaOH solution to determine the volume of methane produced. At the end of the kinetics, pH, and COD were determined; likewise, the results of methane production were analyzed to determine the kinetic parameters using the modified Gompertz model (Eq. 2) [21].

(2)

Where P is the cumulative methane production (mL), Pmax is the maximum methane production (mL), Rmax is the maximum methane production rate (mL/day), t is the time (days), and λ is the lag phase (days). Parameters were estimated using Statistic Six Sigma 13 with minimal sum-of-squares residual errors between the experimental data and the model curves. Additionally, analysis of variance and Tukey test were performed with statistical software (InfoStat) to determine differences between means (p < 0.05).

To carry out the second phase, based on the results obtained in the first experimental phase, the iron-free GAC was selected to be added into a tank reactor with continuous stirring (150 rpm) at 37 ºC for 20 days, with an operating volume of 2 L, initial pH of 12.54 that was adjusted to 7.05, during the operation it was regulated to pH 7.1, using a NaOH solution (5M), this pH was selected because it favors the metabolism of methanogenic bacteria, the reactor was inoculated with 1 g SSV/L of granular anaerobic sludge and 10 g/L of the selected conductive material was added. The initial CODs was 12392 ± 153 mg/L. 2 mL were taken each day to evaluate CODs, which was previously centrifuged at 5000 rpm for 5 minutes. The methane produced was quantified by an automatic methane meter (AMPTS II equipment from BPC Instruments, Sweden); the composition of the gas produced was a gas chromatograph (Shimadzu Nexis GC-2030), equipped with a polar capillary column (ZB-624PLUS, 30 m length, 0.32 mm diameter, 1.0 μm film thickness), in the same equipment ethanol, acetic, propionic and butyric acids were determined from liquid samples taken periodically, previously centrifuged at 5000 rpm for 5 minutes and filtered through a 0.22 μm membrane.

III. RESULTS AND DISCUSSION

Nejayote wastewater is a complex effluent with a high variation in COD; this may be due to the tortilla production method, type of corn, quality of water used, amount of lime, and cooking time [22]. Nejayote water cannot be treated by a biological system without prior conditioning, specifically pH adjustment, due to its high alkalinity, inhibiting microorganism’s metabolism. To achieve DA, it is necessary to consider that if the objective is to produce methane, the pH must range between 6.8 and 7.2 [23].

A. First experimental phase: impact of different percentages of Fe in activated carbon to increase methane production during anaerobic digestion of nejayote

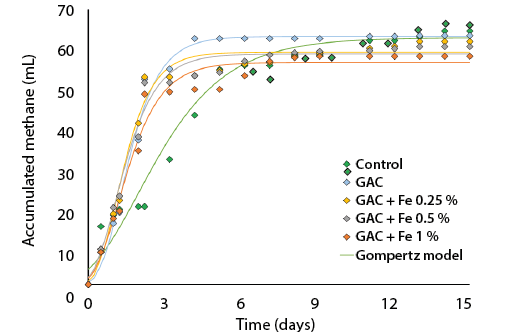

The results of accumulated methane volume are shown in Fig. 2, in order from highest to lowest production for each condition evaluated: Control>GAC>GAC + Fe 0.25 % > GAC + Fe 0.5 % > GAC + Fe 1 %. The accumulated volume does not show a significant difference between the control and GAG with the lowest Fe loads (0.25 and 0.5 %). On the other hand, the CAG with the highest load obtained the lowest methane production (56.5 mL), being 14 % lower than the control. Use trace metals like Fe, Co and Ni has been proved to stimulate the growth of anerobic microorganisms and improve bacteria activity and increase the yield of gas [24], [25]. Nonetheless, research reported in 2024, where they evaluated GAC impregnated with 1.5 and 3 % of Fe, values higher than those carried out in this work, suggests that the increase in the metal load blocks the pores of the GAC, which limits the interaction between the effluent and the microbial consortium [26]. The increase in the metal load in the GAG does not favor methane production with treat nejayote.

The final COD are shown in Table 1, the highest GAC + Fe 0.5 % had the highest COD consumption, followed by GAC + Fe 0.25 %. GAC reduced COD by 23 % more compared to the control. GAC + Fe 1% only reduced COD by 7.3 % less than the final control value. The results with a lower metal load (Fe 0.25 %) favor a reduction in organic load, however, the DIET mechanism is not promoted because it does not increase methane production.

Fig. 2. Production of accumulated methane from nejayote DA with Fe-impregnated conductive materials.

Carbon-based conductive materials have been widely used to stimulate the DIET by enhancing electron transfer for methane production [27], especially the use of GAC, due to their electrical conductivity, surface area, biofilm formation capacity, corrosion resistance, and potentially toxic substance adsorption capacity [28], [29]. Depending on the type of GAC, the adsorption mechanism can occur through physical interactions (microporosity and particle size) and chemical interactions (elemental composition, functional groups, and point of zero charge) [30]. In order to select the material that can achieve the best performance for producing methane, not only its properties and characteristics must be considered, but it will also depend on the interaction between the microbial consortium and the working medium, which is the case in nejayote. According to the results, the CAG does manage to reduce the organic load present in the nejayote, compared to the GAC impregnated with Fe and the control. For this reason, the Gompertz kinetic parameters will be crucial to determine the selection of the conductive material.

TABLE I. FINAL pH, REMOVAL COD AND ACCUMULATED METHANE OF ANAEROBIC DIGESTION OF NEJAYOTE WITH GAC and GAC WITH DIFFERENT PERCENTAGES OF FE

|

Condition |

Final COD (mg/L) |

Removal COD (%) |

Accumulated methane (mL) |

Final pH |

|

Control |

8,596.6 |

45.2 |

64.4 |

4.78 |

|

GAC |

6602.5 |

57.9 |

63.3 |

4.72 |

|

GAC + Fe 0.25% |

5875.0 |

62.5 |

61.8 |

4.76 |

|

GAC + Fe 0.5% |

5300.8 |

66.2 |

60.5 |

4.72 |

|

GAC + Fe 1% |

7965.0 |

49.2 |

56.5 |

4.71 |

|

|

|

|

|

|

The kinetic parameters obtained from the accumulated methane production, according to the maximum methane production, GAG obtained the highest value (66.11 mL), followed by the control (62.81 mL), while the GAC impregnated with Fe obtained similar values, with an average of 58.09 mL ± 1.13 mL, all conditions do not show statistically significant difference between them (Tukey test p < 0.005), this reiterate that adding iron salts does not stimulate methane production when the medium is nejayote. The use of GAG + magnetite was reported, in concentrations of 20 to 40 g/L with dairy industry wastewater, which also has a highly alkaline pH, has been reported, achieving an 80% increase in the methane production rate and a 90% increase in methane conversion [31]. The difference in the results suggests that the interactions between the conductive material, medium, and consortium change according to the origin and composition of the wastewater, even when they share physicochemical characteristics, such as alkalinity and organic matter content.

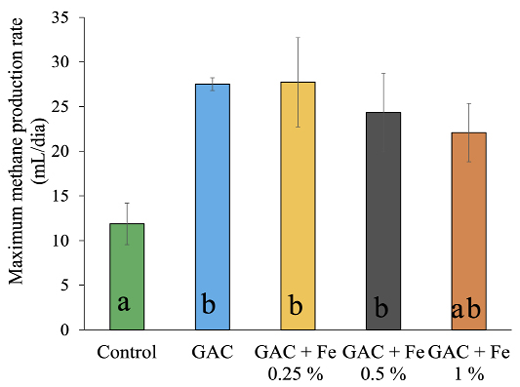

The Rmax results (Fig. 3) show the impact of the conductive material on the DA process, where the production rate is stimulated by the effect of the DIET, being 2.3 times faster GAC and GAG + Fe 0.25 % with respect to the control, while GAG with 0.5 and 1.0 % of Fe, were 2 times faster compared to the control. Therefore, GAC without metal loading can produce faster and higher volumes of methane since there is a statistically significant difference with respect to the control and GAC with iron (Tukey test p < 0.005). Iron can be easily dissolved, allowing it to be used as a micronutrient in methanogenesis in different ways, both positive and negative, all depending on its physicochemical properties and its syntrophic partners [32], which directly influences methane production.

The efficiency of methane production is one of the most important criteria during anaerobic digestion [33], there are several factors that influence it, such as pH, temperature, inoculum, among others; however, the pH value is the fundamental factor. The final average pH of the conditions tested was 4.73 (Table 1), this can cause inhibition for the methanogenic consortium, which is why methane production can be stopped; The optimal pH range to obtain the maximum methane yield in anaerobic digestion is 6.5 to 7.5, the range is relatively wide on the plant scale and the optimal pH value varies with the type of effluent and mode of operation [34]. It is highly recommended to keep this physical parameter at neutral values to promote COD consumption, which can allow high methane production.

Fig. 3. Maximum methane production rate (Rmax) determined from Gompertz model.

B. Second experimental phase: production and composition of biogas in CSTR added with conductive material.

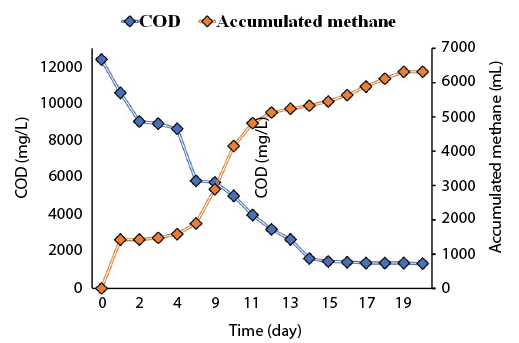

The use of a CSTR reactor allows the control of the pH in an optimal range for methane production. The results showed that the COD was reduced by 88 %, considering the initial and final values. At the end of the kinetics, the accumulated methane volume was 6312 mL. Fig. 4 shows the COD consumption over time, in contrast to the generation of produced methane. GAC has been used before in real and synthetic effluents, reporting values ranging from 60 to 70 % in methane production with residual water from the brewing industry with 5 g GAC/L [35]; with residual activated sludge with 27 g GAC/L, an increase of 37 % in methane production [36]. GAC is a material that stimulates the DIET process by promoting electron transfer. Fig. 4 shows a null lag phase and a direct relationship between the consumption of organic matter and methane production obtained from the DA of nejayote, which has not been previously reported.

Fig. 4. Methane production and COD consumption of nejayote DA with GAC.

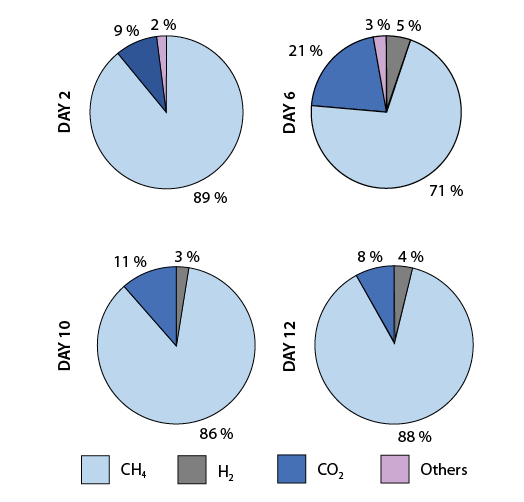

In several studies, the increase of methane content in the biogas produced has been reported when GAC is added to AD systems [37], [38]. Fig. 5 shows the biogas composition produced during days 2, 6, 10, and 12; the percentage of methane during the first days confirms methanogenic activity, with values close to 90%, positively impacting the methane production rate. However, the percentage of methane in the biogas is reduced on day 6; this may be due to a change in the composition of the medium or a change in the metabolic route by the consortium since there is a considerable increase in the CO2 content, however, from day 10, the methane content remained between 85-90% approximately, suggesting that GAC promotes DIET by significantly increasing the methane content in the biogas produced during the AD of nejayote. The typical composition of CH4 is reported to be between 50 to 75 % and CO2 to be between 25 and 50 % [39]. GAC could allow biomethane generation from the anaerobic digestion of nejayote, representing an alternative energy source.

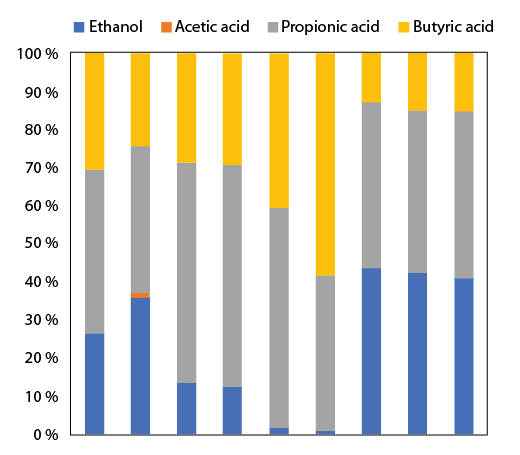

Fig. 5. Composition of biogas produced during AD of nejayote with GAC.

The final pH was 7.31, which favors the methanogenic consortium due to the high consumption of organic matter. The acidification obtained in the first experimental phase could occur due to the accumulation of organic acids, such as volatile fatty acids (propionic, butyric, valeric, among others). Fig. 6 shows the production of ethanol (ET), acetic acid (AA), propionic acid (PA) and butyric acid (BA). Raw nejayote contains 26.5 % ET, 42.9 % AP, and 30.5 % BA. During the first days, the concentration of these intermediate products increases. From the fifth day on, the ET is reduced to 12 %, decreasing as the days go by until reaching values of 1 %, causing an accumulation of PA and BA.

GAC stimulates DIET through the consumption of VFA [40]; however, the accumulation of PA and BA, which are compounds not directly consumed by methanogenic bacteria, favors the stabilization of methanogenic microorganisms [41]. Therefore, it is necessary to continue evaluating the different conductive materials to understand better and describe the interactions between the medium, microorganisms, and the tested material. It is advisable to work with a controlled medium, where the optimal pH range of the metabolism of the microorganisms of the producer of interest is maintained, methane being the objective of this work, to interpret a response and behavior mechanism. This allows to continue developing research and to be able to generate a universally accessible database to consider proposals to treat a complex effluent such as that of the nixtamalization process.

Fig. 6. VFA production during AD of nejayote with GAC.

IV. CONCLUSIONS

Nejayote is a complex effluent, which represents a challenge for its treatment, where DA is a viable option, which promotes an energetic valorization of said effluent, methane is an alternative source of energy with a calorific value higher than that of hydrocarbons. The GAC modified with iron does not stimulate the direct transfer of electrons when the aqueous medium is nejayote. The GAC promotes the DIET mechanism, increasing the consumption of organic matter and AGV, increasing the methane production rate and significantly reducing the lag phase. This study represents a precedent for understanding the syntrophic interactions between the species of anaerobic microorganisms, type of residual water, and conductive material. Future research is proposed to promote the generation of alternative energy sources and establish sustainable treatment strategies, even in complex waters, such as nejayote.

Notas

* Corresponding autor: luis.alvarez@itson.edu.mx

1. Vianey A. Burboa Charis. Dpto. Biotecnología y Ciencias Alimentarias, Instituto Tecnológico de Sonora, Ciudad Obregon, Sonora, México. vburboach@gmail.com, ORCID number https://orcid.org/0000-0001-7210-7219

2. Margarita Sarai Escalante Torres. Dpto. Ciencias del Agua y Medio Ambiente, Instituto Tecnológico de Sonora, Ciudad Obregon, Sonora, México. E-mail: Margarita.escalante213000@potros.itson.edu.mx.

3. Miguel A. Armenta. Dpto. Biotecnología y Ciencias Alimentarias, Instituto Tecnológico de Sonora, Ciudad Obregon, Sonora, México. E-mail: angel456_1@hotmail.com, ORCID number https://orcid.org/0000-0001-7865-618X

4. Lourdes M. Tenorio Diaz. Dpto. Biotecnología y Ciencias Alimentarias, Instituto Tecnológico de Sonora, Ciudad Obregon, Sonora, México. E-mail: lourdes.diaz@itson.edu.mx, ORCID number https://orcid.org/0000-0002-8941-3965

5. Luis A. Leyva Soto. Dpto. Biotecnología y Ciencias Alimentarias, Instituto Tecnológico de Sonora, Ciudad Obregon, Sonora, México. E-mail: luis.leyva@itson.edu.mx, ORCID number https://orcid.org/0000-0002-8101-7925

6. Angel R. Meza. Dpto. Biotecnología y Ciencias Alimentarias, Instituto Tecnológico de Sonora, Ciudad Obregon, Sonora, México. E-mail: angel_esquer@hotmail.com, ORCID number https://orcid.org/0000-0002-4048-8958

7. Luis H. Álvarez. Dpto. Biotecnología y Ciencias Alimentarias, Instituto Tecnológico de Sonora, Ciudad Obregon, Sonora, México. E-mail: luis.alvarez@itson.edu.mx, ORCID number https://orcid.org/0000-0003-1809-9304.

IV. REFERENCES

[1] Secretaría de Agricultura y Desarrollo Rural, S. (s. f.). Maíz, cultivo de México. (2023). https://www.gob.mx/agricultura/articulos/maiz-cultivo-de-mexico#:~:text=Cultivo%20de%20ma%C3%ADz%20en%20M%C3%A9xico,los%2032%20estados%20del%20pa%C3%ADs.

[2] Quintero-Herrera S., Rueda Avellaneda J., Zwolinski P., Evrard D., Rivas-García P. (2023). Towards a cleaner Mexican tortilla industry: a prospective life cycle assessment approach, Procedia CIRP, Volume 116, 2023, Pages 504-509, ISSN 2212-8271, https://doi.org/10.1016/j.procir.2023.02.085.

[3] M. v. Espejel-García, J.S. Mora-Flores, J.A. García-Salazar, S. Pérez Elizalde, R. García-Mata, Caracterización del consumidor de tortilla en el Estado de México, Agricultura Sociedad y Desarrollo. 13 (2016) 371. https://doi.org/10.22231/asyd.v13i3.401.

[4] Valenzuela E., Gutiérrez-Uribe J., Franco-Morgado M., Cervantes-Avilés P. (2024). Navigating the waters of nixtamalization: Sustainable solutions for maize-processing wastewater treatment, Science of The Total Environment, Volume 911, 2024, 168674, ISSN 0048-9697, https://doi.org/10.1016/j.scitotenv.2023.168674.

[5] Paredes López, O., Guevara Lara, F., & Bello Pérez, L. A. (2010). La nixtamalización y el valor nutritivo del maíz. Ciencias, 92(092). Recuperado a partir de https://www.revistas.unam.mx/index.php/cns/article/view/14831.

[6] Teresa Zayas, Alejandra de Gante, María Guadalupe Tenorio Arvide, Miriam Vega Hernández, Guillermo Soriano-Moro, Leonardo Salgado, Treatment of nixtamalization wastewater (nejayote) using electrocoagulation and combined chemical coagulation/electrocoagulation processes, Desalination and Water Treatment, Volume 280, 2022, Pages 44-51, ISSN 1944-3986, https://doi.org/10.5004/dwt.2022.29113.

[7] Martínez-Bustos, F., Martínez-Flores, H. E., Sanmartín-Martínez, E., Sánchez-Sinencio, F., Chang, Y. K., Barrera-Arellano, D., & Rios, E. (2001). Effect of the components of maize on the quality of masa and tortillas during the traditional nixtamalisation process. Journal of the Science of Food and Agriculture, 81(15), 1455–1462. https://doi.org/10.1002/jsfa.963

[8] Velasco-Martinez M, Angulo O, Vazquez-Couturier DL, Arroyo-Lara A, Monroy-Rivera JA. Effect of dried solids of nejayote on broiler growth. Poult Sci. 1997 Nov;76(11):1531-4. https://doi.org/10.1093/ps/76.11.1531.

[9] Salmerón-Alcocer, A., Rodríguez-Mendoza, N., Pineda-Santiago, V., Cristiani-Urbina, E., Juárez-Ramírez, C., Ruiz-Ordaz, N., & Galíndez-Mayer, J. (2003). Aerobic treatment of maize-processing wastewater (nejayote) in a single-stream multi-stage bioreactor. Journal of Environmental Engineering and Science, 2(5), 401-406. https://doi.org/10.1139/s03-046

[10] Díaz-Montes, E., Castro-Muñoz, R., & Yáñez-Fernández, J. (2016). An overview of nejayote, a nixtamalization by product. Ingeniería Agrícola y Biosistemas, 8(2), 41-60. https://doi.org/10.5154/r.inagbi.2016.03.002

[11] España-Gamboa, E., Domínguez-Maldonado, J.A., Tapia-Tussell, R. et al. Corn industrial wastewater (nejayote): a promising substrate in Mexico for methane production in a coupled system (APCR-UASB). Environ Sci Pollut Res 25, 712–722 (2018). https://doi.org/10.1007/s11356-017-0479-z

[12] Román-Escobedo, L.C.; Cristiani-Urbina, E.; Morales-Barrera, L. Bioremediation with an Alkali-Tolerant Yeast of Wastewater (Nejayote) Derived from the Nixtamalization of Maize. Fermentation 2024, 10, 219. https://doi.org/10.3390/fermentation10040219

[13] Meraz, K. A. S., Vargas, S. M. P., Maldonado, J. T. L., Bravo, J. M. C., Guzman, M. T. O., & Maldonado, E. A. L. (2016). Eco-friendly innovation for nejayote coagulation–flocculation process using chitosan: Evaluation through zeta potential measurements. Chemical Engineering Journal, 289, 536-542. https://doi.org/10.1016/j.cej.2015.09.026.

[14] Khanh Nguyen, V., Kumar Chaudhary, D., Hari Dahal, R., Hoang Trinh, N., Kim, J., Chang, S. W., … Nguyen, D. D. (2021). Review on pretreatment techniques to improve anaerobic digestion of sewage sludge. Fuel, 285, 119105. https://doi.org/10.1016/j.fuel.2020.119105

[15] Campos-Flores, R.C.; Reyna-Gómez, L.M.; Suárez-Vázquez, S.I.; Robledo-Olivo, A.; Cruz-López, A. Effect of Inoculum Pretreatment and Operational Mode of Reactor on BioH2 Production from Nixtamalization (Nejayote) and Abattoir Wastewater. Waste Biomass Valor. 2023, 15, 2145–2158.

[16] Rotaru AE, Shrestha PM, Liu F, et al (2014) Direct interspecies electron transfer between Geobacter metallireducens and Methanosarcina barkeri. Appl Environ Microbiol 80:4599–4605. https://doi.org/10.1128/AEM.00895-14

[17] Fang, Z., Huang, Y., Tang, S. et al. Direct interspecies electron transfer for environmental treatment and chemical electrosynthesis: A review. Environ Chem Lett 22, 3107–3133 (2024). https://doi.org/10.1007/s10311-024-01774-8

[18] Kato S, Hashimoto K, Watanabe K (2012) Methanogenesis facilitated by electric syntrophy via (semi)conductive iron-oxide minerals. Environ Microbiol 14:1646–1654. https://doi.org/10.1111/j.1462-2920.2011.02611.x

[19] Burboa Charis, V. A., Orrantia López, M., & Alvarez Valencia, L. H. (2023). Electron transfer via conductive materials and their impact on the anaerobic methane production. Entreciencias: Diálogos En La Sociedad Del Conocimiento, 11(25), 1–17. DOI: https://doi.org/10.22201/enesl.20078064e.2023.25.85046

[20] Armenta MA, Maytorena VM, Buentello-Montoya DA, Arroyo E, Cota-Leal M, Yong D, et al. Effect of catalytic hydrodynamics over microagglomerates of Mn2O3 and PdO supported on γ-χ-Al2O3 for dimethyl ether production. Fuel 2022;317: 123509.

[21] Lin CY, Lay CH. Effects of carbonate and phosphate concentrations on hydrogen production using anaerobic sewage sludge microflora. Int J Hydrogen Energy. 2004;29(3):275-281. https://doi.org/10.1016/j.ijhydene.2003.07.002

[22] Argun, M. S., & Argun, M. E. (2017). Treatment and alternative usage possibilities of a special wastewater: Nejayote. Journal of Food Process Engineering, 41(1), e12609. https://doi.org/10.1111/jfpe.12609

[23] Wang S, Yuan R, Liu C, Zhou B. Effect of Fe2+ adding period on the biogas production and microbial community distribution during the dry anaerobic digestion process. Process Saf Environ Prot. 2020 Jan 1;136:234–41. https://doi.org/10.1016/j.jenvman.2022.116783

[24] Zhang, W., Wu, S., Guo, J., Zhou, J., & Dong, R. (2015). Performance and kinetic evaluation of semi-continuously fed anaerobic digesters treating food waste: Role of trace elements. Bioresource Technology, 178, 297–305. https://doi.org/10.1016/j.biortech.2014.08.046

[25] Wei, Q., Zhang, W., Guo, J., Wu, S., Tan, T., Wang, F., & Dong, R. (2014). Performance and kinetic evaluation of a semi-continuously fed anaerobic digester treating food waste: Effect of trace elements on the digester recovery and stability. Chemosphere, 117, 477–485. https://doi.org/10.1016/j.chemosphere.2014.08.060

[26] Orrantia, Miriam, Armenta, M.A., Alvarez, Luis H., Burboa-Charis, Vianey A.,Meza-Escalante, Edna R., Olivas, A., Arroyo, E., Maytorena, V.M. (2024). Enhanced methane production via anaerobic digestion assisted with Fe3O4 nanoparticles supported on microporous granular activated carbon, Fuel, Volume 360,130517, ISSN 0016-2361, https://doi.org/10.1016/j.fuel.2023.130517.

[27] Jiaji Sun, Eldon R. Rene, Yuhe He, Weifang Ma, Qian Hu, Bin Qiu (2023). Carbon, iron, and polymer-based conductive materials for improving methane production in anaerobic wastewater treatment systems: A review on their direct interspecific electron transfer mechanism, Fuel, Volume 342, 2023, 127703, ISSN 0016-2361, https://doi.org/10.1016/j.fuel.2023.127703.

[28] Watanabe, K. (2008) Recent Developments in Microbial Fuel Cell Technologies for Sustainable Bioenergy. Journal of Bioscience and Bioengineering, 106(6), 528–536. [online] http://dx.doi.org/10.1263/jbb.106.528.

[29] Pham, T. H., Aelterman, P., & Verstraete, W. (2009). Bioanode performance in bioelectrochemical systems: recent improvements and prospects. Trends in Biotechnology, 27(3), 168–178. https://doi.org/10.1016/j.tibtech.2008.11.005

[30] Gulizhaer Abulikemu, David G. Wahman, George A. Sorial, Mallikarjuna Nadagouda, Eva K. Stebel, Erika A. Womack, Samantha J. Smith, Eric J. Kleiner, Brooke N. Gray, Rose D. Taylor, Cameron X. Gastaldo, Jonathan G. Pressman, Role of grinding method on granular activated carbon characteristics, Carbon Trends, Volume 11, 2023, 100261, ISSN 2667-0569, https://doi.org/10.1016/j.cartre.2023.100261.

[31] Zhao, Z., Li, Y., Quan, X., & Zhang, Y. (2017). Towards engineering application: Potential mechanism for enhancing anaerobic digestion of complex organic waste with different types of conductive materials. Water Research, 115, 266–277. https://doi.org/10.1016/j.watres.2017.02.067

[32] Gahyun Baek, Jinsu Kim, Changsoo Lee, A review of the effects of iron compounds on methanogenesis in anaerobic environments, Renewable and Sustainable Energy Reviews, Volume 113, 2019, 109282, ISSN 1364-0321, https://doi.org/10.1016/j.rser.2019.109282.

[33] Molnar, L., & Bartha, I. (1989). Factors influencing solid-state anaerobic digestion. Biological Wastes, 28(1), 15-24. https://doi.org/10.1016/0269-7483(89)90045-1

[34] LIU, C., YUAN, X., ZENG, G., LI, W., & LI, J. (2008). Prediction of methane yield at optimum pH for anaerobic digestion of organic fraction of municipal solid waste. Bioresource Technology, 99(4), 882–888. https://doi.org/10.1016/j.biortech.2007.01.013

[35] Xu, S., He, C., Luo, L., Lü, F., He, P. y Cui, L. (2015). Comparing Activated Carbono f Different Particle Sizes on Enhancing Methane Generation in Upflow Anaerobic Digester. Bioresource Technology, 196. 606-612. http://dx.doi.org/10.1016/j.biortech.2015.08.018.

[36] Peng, H., Zhang, Y., Tan, D., Zhao, Z., Zhao, H., & Quan, X. (2018). Roles of magnetite and granular activated carbon in improvement of anaerobic sludge digestion. Bioresource Technology, 249, 666–672. https://doi.org/10.1016/j.biortech.2017.10.047

[37] Lee, J., Lee, S., and Park, H. (2016) Bioresource Technology Enrichment of specific electro-active microorganisms and enhancement of methane production by adding granular activated carbon in anaerobic reactors. BIORESOURCE TECHNOLOGY, 205, 205–212. [online] http://dx.doi.org/10.1016/j.biortech.2016.01.054.

[38] Yang Y, Zhang Y, Li Z, et al (2017) Adding granular activated carbon into anaerobic sludge digestion to promote methane production and sludge decomposition. J Clean Prod 149:1101–1108. https://doi.org/10.1016/J.JCLEPRO.2017.02.156

[39] Bhatt, A. H., & Tao, L. (2020). Economic Perspectives of Biogas Production via Anaerobic Digestion. Bioengineering, 7(3), 74. https://doi.org/10.3390/bioengineering7030074

[40] Mou, A., Yu, N., Yang, X., & Liu, Y. (2024). Enhancing methane production and organic loading capacity from high solid-content wastewater in modified granular activated carbon (GAC)-amended up-flow anaerobic sludge blanket (UASB). Science of the Total Environment, 906, 167609. https://doi.org/10.1016/j.scitotenv.2023.167609

[41] Gallert, C., and Winter, J. 2008. Propionic acid accumulation and degradation during restart of a full-scale anaerobic biowaste digester. Bioresour. Technol. 99(1): 170–178. https://doi.org/10.1016/j.biortech.2006.11.014.