Journal Information

Title: Enfoque UTE

Editor-in-Chief: Diego Guffanti

Associate Editor: Carlota Martina Moreno

Copyright: 2025, The Authors

Volume: 16 Issue: 3

ISSN (electronic): 1390-6542

Copyright statement: License (open-access,

https://creativecommons.org/licenses/by/4.0/)

Article Information

Date received: APRIL 4, 2025

Date accepted: MAY 29, 2025

Publication date: JULY 1, 2025

Date of current version: JULY 1, 2025

Publisher: Universidad UTE (Quito, Ecuador)

Pages: 44-51

DOI: https://doi.org/10.29019/enfoqueute.1164

http://ingenieria.ute.edu.ec/enfoqueute/

Development and physical-chemical and microbiological characterization of a yogurt-like product, lupine (Lupinus mutabilis Sweet) -based

Monserrath Vásquez1*, Clara Villacrés2, María Morales3, Josué Cruz4

Abstract

In view of the growing demand for alternatives to animal products, this study presents the development and physicochemical, microbiological and sensory characterization of a yogurt-type product based on lupine milk (Lupinus mutabilis) and starch from arracacha (Arracacia xanthorrhiza). Three versions of the product were formulated with different concentrations of starch, evaluating its proximal composition, polyphenol content, rheological behavior, microbiological profile and sensory acceptance. The results showed that the incorporation of starch did not significantly affect the basic nutritional composition, maintaining an adequate protein and fiber profile. The formulation with 3 % starch (T3) presented higher viscosity, rheological stability and sensory acceptability analysis, standing out in attributes such as flavor, texture and appearance. In addition, the pseudoplastic behavior observed suggests a favorable texture for the consumer. At the microbiological level, all formulations met safety standards, showing an adequate presence of lactic acid bacteria with probiotic potential. Therefore, this work not only highlights the potential of lupin as a base for functional fermented products but also highlights the importance of arracacha starch as a natural stabilizer. The findings open new perspectives for the development of innovative, sustainable and nutritionally balanced plant-based foods, with projection towards the food industry and the growing market of vegan and food intolerant consumers.

Keywords

milk-like; yogurt-like; Arracacia xanthorrhiza; Lupinus mutabilis Sweet; lactic acid bacteria.

Resumen

Ante la creciente demanda de alternativas a productos de origen animal, este estudio presenta el desarrollo y caracterización fisicoquímica, microbiológica y sensorial de un producto tipo yogurt a base de leche de lupino (Lupinus mutabilis) y almidón de arracacha (Arracacia xanthorrhiza). Se formularon tres versiones del producto con diferentes concentraciones de almidón, evaluando su composición proximal, contenido de polifenoles, comportamiento reológico, perfil microbiológico y análisis de aceptabilidad sensorial. Donde los resultados evidenciaron que la incorporación de almidón no afectó significativamente la composición nutricional básica, manteniendo un perfil proteico y de fibra adecuado. La formulación con 3 % de almidón (T3) presentó mayor viscosidad, estabilidad reológica y aceptabilidad sensorial, destacándose en atributos como sabor, textura y apariencia. Además, el comportamiento pseudoplástico observado sugiere una textura favorable para el consumidor. A nivel microbiológico, todas las formulaciones cumplieron con los estándares de inocuidad, mostrando una adecuada presencia de bacterias ácido-lácticas con potencial probiótico. Teniendo que este trabajo no solo destaca el potencial del lupino como base para productos fermentados funcionales, sino que también resalta la importancia del almidón de arracacha como estabilizante natural. Los hallazgos abren nuevas perspectivas para el desarrollo de alimentos vegetales innovadores, sostenibles y nutricionalmente balanceados, con proyección hacia la industria alimentaria y el mercado creciente de consumidores veganos y con intolerancias alimentarias.

Palabras Clave

parecido a la leche, parecido al yogur, Arracacia xanthorrhiza; Lupinus mutabilis Sweet; bacterias ácido – lácticas.

I. INTRODUCTION

THE rejection of animal-derived products has increased notably in recent years, a trend closely associated with veganism—a dietary practice that excludes all animal-origin foods, including dairy, honey, and eggs [1]. The number of individuals identifying as vegans continues to grow, driven by motivations such as improving health and avoiding animal cruelty. Within this context, plant-based dairy alternatives have gained significant attention due to their suitability for individuals with allergies, lactose intolerance, or those transitioning to a vegan lifestyle [2].

A parallel rise in the adoption of healthier lifestyles has led consumers to seek out plant-based and functional food options [3]. Among these, plant-based yogurts stand out due to their low cholesterol content and their suitability for individuals with protein allergies or lactose intolerance [4]. Moreover, these yogurts retain high levels of probiotics and bioactive peptides, which enhance their nutritional value [2]. The texture and nutritional profile of such products depend significantly on the type of plant-based milk used (e.g., legumes or cereals) and on complementary ingredients such as starch and fiber [1]. As a result, the food industry has increasingly focused on developing plant-based functional foods that promote consumer health [5].

However, studies on plant-based yogurt alternatives have faced several limitations. Some formulations derived from legumes such as soy, pea, or oat often struggle to achieve desirable sensory attributes, particularly in terms of flavor, texture, and aroma, most notably the presence of off-flavors and insufficient creaminess [6]. Furthermore, the low gelling capacity of plant proteins compared to dairy proteins has led to the addition of stabilizers or texture enhancers, which can sometimes compromise the natural or clean-label appeal of the products [7]. Another common limitation has been the variability in the growth of probiotic cultures in non-dairy matrices, which can affect the viability and stability of probiotics over the shelf-life of the products [8], [9]. Also considering that few studies have explored the use of alternative starches such as arracacha (Arracacia xanthorrhiza) to improve texture, focusing predominantly on more commonly available sources such as corn or potato starch [10], [11]. These limitations highlight the need for further research into novel plant-derived matrices and stabilizers that can improve the physicochemical, microbiological and sensory qualities of yogurt-like products without compromising their nutritional profile or clean-label appeal [7], [12].

For this reason, the formulation of plant-based yogurts requires the selection of legumes with high protein content. Among these, lupine (Lupinus spp.) stands out for its exceptional protein concentration, ranging between 40 and 50 g/100 g dry weight [13]. Although the genus Lupinus includes nearly 300 species, only four are of major agricultural significance: L. albus, L. angustifolius, L. luteus, and L. mutabilis. The latter is particularly noteworthy for its high protein content, adaptability to agricultural systems, and potential health benefits [14]. According to the [15], lupine contains approximately 51 % protein, 21.9 % fat, 13 % fiber, 3.23 % alkaloids, 0.37 % calcium, 0.6 % iron, and 0.3 % zinc. However, due to its elevated alkaloid content, it must be subjected to heat treatment to reduce these compounds and minimize the risk of toxicity [1].

Lupine proteins include heat-stable globulins such as α-conglutin (11S legumin-type) and β-conglutin (7S vicilin-type). The denaturation of β-conglutin begins at 85-89 °C, while α-conglutin remains stable up to 102-105 °C. Under high temperatures and isoelectric pH, these globular proteins unfold due to the disruption of hydrogen bonds and hydrophobic interactions, leading to the formation of protein aggregates. These can bind to albumins, which possess excellent interfacial properties, contributing to foam formation and reduced interfacial tension [4], [16]. Heat and bacterial proteolysis further induce structural changes such as denaturation, dissociation, and aggregation, enhancing the yogurt’s structural, functional, and nutritional characteristics [17]. Nevertheless, lupine has inherently weak gelling properties, which is why starch is often added to improve mouthfeel, viscosity, creaminess, reduce syneresis, and enhance gel firmness [18].

Therefore, the objective of this study was to develop a yogurt-like product based on lupine milk and Arracacia starch as an alternative to traditional dairy products, and to evaluate its physicochemical, microbiological, and sensory characteristics.

II. MATERIALS AND METHODS

A. Materials

Commercial lupine grain of the INIAP-450 variety was purchased from the Gralyn farm in Latacunga, Ecuador. Arracacia xanthorrhiza starch was provided by the Plant Genetic Resources Department of INIAP-Ecuador. Danisco (Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus) and sucrose were purchased from the chemist’s house in Latacunga, Ecuador.

B. Lupine debittering

The lupine grains were debittered using aqueous heat processing as previously reported [19]. Briefly, grains were immersed in hot water (80 ◦C) at a 1:3 ratio (grain:water) for 10 h, then cooked at 91 ◦C for 1 h and thoroughly washed at 35 ◦C for 28 h with continuous changing of distilled water.

C. Milk-like product processing

In the preparation of the lupine-based milk product, the grain previously free of bitterness was used, which was ground in a colloid mill (Wenzhou Maolong Machinery Co., Ltd, China) applying a water:grain ratio of 1:4 w/v [20].

D. Yogurt-like product, lupin-based processing

For yogurt-like processing, a milk-like lupin base (1.84 % fat w/w) was used. Preliminary trials were conducted to define the inclusion levels of A. xanthorrhiza starch in yogurt-like product and the following test formulations were established: T1= (90.7 % milk-like, 1 % A. xanthorrhiza starch, 8 % sucrose, 0.3 % Danisco strain), T2= (89.7 % milk-like, 2 % A. xanthorrhiza starch, 8 % sucrose, 0.3 % Danisco strain) and T3= (88.7 % milk-like, 3 % A. xanthorrhiza starch, 8 % sucrose, 0.3 % Danisco strain).

All three formulations were pasteurized at 70 °C for 30 minutes and then cooled to 40 °C. They were then incubated at 40 °C ± 2 °C for 10 to 12 hours in an incubator (Memmert, Germany) until the pH was adjusted to a range of 4.4 to 4.6. To stop the fermentation process, the yogurts were removed from the incubator and stored under refrigeration at 4 °C.

E. Proximal analysis

Methodologies of the AOAC were used to assess moisture (930.15), crude protein (total N x 6.25) (955.39), crude fat (920,39), crude fiber (978.10), and ash (942.05). The total carbohydrate content of the samples was calculated by the difference method (subtracting the percent crude protein, crude fiber, crude fat, and ash from 100 %), [21]. The energy content was determined by applying the method described by [22].

F. Polyphenols

The total phenolic content was determined using the Folin Ciocalteu 2N reagent. The absorbance was measured at 754 nm using an Evolution 201 spectrophotometer (Cachay-Morante et al., 2022) (Thermo Fisher Scientific, Massachusetts, USA), and the results are expressed in mg of gallic acid/100 g of dry sample [23].

G. pH and titratable acidity

During fermentation, standard methodologies of the Association of Official Analytical Chemical International were used to assess pH (943.02) and total titratable acidity (947.05) [24]. The pH value and total titratable acidity were determined using 10 mL of samples which were suspended in 90 mL distilled water and stirred for 10 min. The pH was measured using a pH electrode, and total titratable acidity was expressed as the amount (mL) of 0.01 mol.L-1 NaOH required to obtain a pH value of 8.2, and the result is reported as lactic acid percentage.

H. Viscosity

Measurements of viscosity were done with Brookfield (model DV II; Brookfield Engineering Laboratories, Stoughton, MA 02072, USA) with Helipath stand, a type D T-bar spindle and a speed of 5 rpm. The Brookfield measurements were performed in triplicate and the mean values used for further analysis were reported. All rheological measurements were made at 5 °C Spindle No 2 from 0 to 200 rpm was used for all samples, as described by [25].

I. Rheological

From the viscosity values obtained using the Brookfield viscometer (model DV II; Brookfield Engineering Laboratories, Stoughton, MA, USA), mathematical modeling was performed using the power law equation [19].

The data obtained were adjusted to the following equation:

(1)

Where:

: shear stress (Pa).

: shear rate (1/s).

: fluid consistency index (Pa.sn).

n: flow behavior index.

This model allowed us to characterize the relationship between shear stress and shear rate, determining whether the yogurt exhibited pseudoplastic, dilatant, or Newtonian behavior.

J. Microbiological Analysis

Microorganism enumeration was performed using the rapid Petrifilm methods (3M). A dilution of each sample was made by adding 10 g of yogurt to 90 ml of distilled water. In all cases, 1 ml of the dilution was inoculated in duplicate and incubated at 25 °C for 48 h for molds and yeasts (AOAC Method 997.02) and 35 °C for 24 h for E. coli/total coliforms (AOAC Method 991.14). At the end of the incubation, plates with between 15 and 150 colonies were selected, and the result was reported as colony-forming units per gram (CFU/g). Microbiological quality was assessed by comparing the results with the requirements established in the Ecuadorian Technical Standard INEN 2395 for Fermented Milks [27].

K. Sensory acceptability analysis

Sixty consumers between 18 and 60 years of age [28], all habitual yogurt consumers, were randomly recruited through advertisements at various locations on the campus of Cotopaxi University, La Maná, Ecuador. They were invited to participate in an acceptance test for four yogurt-like products with different concentrations of Arracacia starch. Each sample contained 20 mL and was presented monadically in coded plastic cups in a randomized order. First-order and carryover effects were balanced using a Randomized Complete Block Design, where each consumer evaluated all yogurt-like samples. The test was conducted under controlled conditions, with water and crackers available to consumers. 9-point hedonic scale (1 – extremely disliked, 2 – very disliked, 3 – moderately disliked, 4 – slightly disliked, 5 – neither liked nor disliked, 6 – slightly liked, 7 – moderately liked, 8 – very liked, and 9 – extremely liked) [29]. Results were subjected to one-way analysis of variance (ANOVA) to identify contrasts between yogurt samples, followed by Tukey’s test with a significance level of 5.00 %.

L. Statistical analysis

All analyses were performed in triplicate; results are expressed as mean ± standard deviation. Data were analyzed using a multivariate ANOVA using the INFOSTAT statistical package (University of Córdoba, Argentina) to compare means with respect to the level of Arracacia starch incorporation. Tukey’s multiple-range test was applied to determine significant differences at the 5 % level. For the rheological component, Python was used, using the numpy and matplotlib libraries.

III. RESULTS AND DISCUSSION

A. Proximal Analysis

A significant difference in moisture content was observed between the milk-like product made from Lupinus mutabilis and the three formulations containing Arracacia xanthorrhiza starch (p ≤ 0.05). The milk-like product showed the highest moisture percentage (92.20 %), which can be attributed to the natural moisture of lupin and the addition of water during processing. In contrast, moisture content decreased progressively with increasing starch concentration, with formulation T3 exhibiting the lowest value (85.59 %). Regarding protein, fat, and energy content, no significant differences were found (p ≥ 0.05) between the starch-containing formulations and the milk-like product, suggesting that the inclusion of Arracacia starch did not substantially alter these parameters. Ash content was higher in treatment T1 (90.7 % compared to the milk-like product, with 1 % Arracacia xanthorrhiza starch, 8 % sucrose, and 0.3 % Danisco culture), although the difference was not statistically significant (p ≥ 0.05) when compared to formulations T2 and T3. This trend may be related to the mineral contribution of Arracacia starch. Similarly, crude fiber content did not show significant differences (p ≥ 0.05) among the three treatments. These results are consistent with those reported by [30], in studies of plant-based yogurts enriched with starch.

TABLE I. PROXIMAL COMPOSITION AND POLYPHENOL CONTENT OF A MILK-LIKE PRODUCT, AND THREE FORMULATIONS OF YOGURT-LIKE PRODUCTS, LUPINE-BASED

|

Milk-like |

T1 |

T2 |

T3 |

|

|

Moisture (%) |

92.20 ± 0.066a |

86.58 ± 0.037b |

86.77 ± 0.143b |

85.59 ± 0.042c |

|

Protein (%) |

2.40 ± 0.061a |

2.39 ± 0.225a |

2.65 ± 0.130a |

2.71 ± 0.060a |

|

Fat (%) |

1.84 ± 0.050a |

1.76 ± 0.027a |

1.83 ± 0.009a |

1.88 ± 0.001a |

|

Crude fiber (%) |

2.66 ± 0.050a |

2.12 ± 0.012b |

2.15 ± 0.015b |

2.25 ± 0.023b |

|

Ash (%) |

0.03 ± 0.005b |

0.05 ± 0.001a |

0.04 ± 0.005ab |

0.04 ± 0.004ab |

|

Carbohydrates (%) |

7.09 ± 0.227ab |

7.08 ± 0.227ab |

6.51 ± 0.022b |

7.54 ± 0.100a |

|

Energy (kcal) |

59.83 ± 1.694a |

58.04 ± 0.257a |

57.75 ± 0.601a |

62.19 ± 0.367a |

|

Polyphenols (mg gallic acid /100 mL) |

3.17 ± 0.386b |

3.09 ± 0.468b |

3.67 ± 0.328a |

3.46 ± 0.368ab |

|

|

|

|

|

|

Different letters in the same row indicate significant differences (p ≤ 0.05). Mean value ± SD (n-3) T1= (90.7 % milk-like, 1% Arracacia xanthorrhiza starch, 8 % saccharose, 0.3 % Danisco starter), T2= (89.7 % milk-like, 2% Arracacia xanthorrhiza starch, 8 % saccharose, 0.3 % Danisco strain) and T3 = (88.7 % milk-like, 3 % Arracacia xanthorrhiza starch, 8 % saccharose, 0.3 % Danisco strain).

B. Polyphenols

The concentration of total phenolic compounds (Table I) in the yogurt-like samples ranged from 3.09 to 3.67 mg gallic acid/100 mL, starting from 3.17 mg/100 mL of milk-type, lupine-based. These results are in agreement with those mentioned by [31] for legume-based fermented products and plant-based fermented beverages, in which they reported 2.8- 4.2 mg gallic acid/100 mL. They indicate that in legumes, many polyphenols are bound to fiber or other macromolecules.

The enzymatic action of microorganisms during fermentation can break these bonds and release polyphenols, increasing their concentration in the final product, [31].

Formulation T2 showed the highest concentration of polyphenols (3.67 mg gallic acid/100 mL), which could be associated with the action of lactic acid bacteria (LAB) used in fermentation, these metabolize certain compounds present in lupine and produce new polyphenols or modify existing ones, improving their bioavailability and antioxidant activity, as reported by [32] in yogurts with functional ingredients. Meanwhile, the T3 formulation (3.46 mg of gallic acid/100 mL) presented a value lower than T2, this difference can be attributed to the higher starch content in its composition. The elevated presence of starch promotes the formation of strong starch–polyphenol interactions, which affect the bioaccessibility of these compounds. As a result, there is a slight decrease in the number of free polyphenols available for detection in the analysis [33]. However, no significant differences (p ≥ 0.05) were found between T2 and T3, suggesting that although the numerical values vary, the changes in polyphenol concentration between these treatments are not statistically relevant. On the other hand, the lowest concentration (3.09 mg gallic acid/100 mL) showed by T1 formulation, may be due to the lower starch content in the formulation. According [26] the contribution of polyphenols to the formulation is 5.51 mg Trolox Eq./g. These results highlight the importance of optimizing the formulation to increase the content of bioactive compounds in yogurts.

C. pH and titratable acidity variation

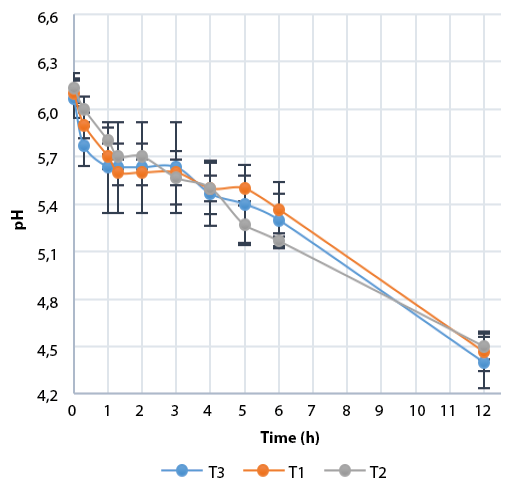

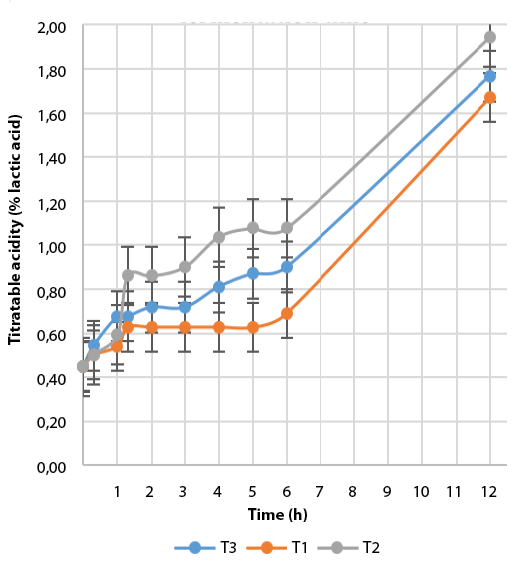

The pH decreased progressively with the fermentation time of milk-like product, while the acidity presented an increase, as evidenced in Figures 1 and 2. This behavior was determined from the first time of fermentation, which was attributed to a greater contact area for the growth of microorganisms and their metabolic activity [34]. A decrease in pH is a desirable result for fermentation, because the opposite effect results in the overproduction of ammonia resulting from the decomposition of nitrogen-containing organic compounds [35]. The results are consistent with that reported by [36], who note that pH reduction is associated with the production of lactic acid and other secondary compounds. These secondary products include acetic, butyric and propionic acids, which contribute to pH decrease and acidification of the medium. The variation recorded was significantly (p ≤ 0.05) dependent on the formulation composition. The greatest difference was observed in the fermentation of T2, with respect to T1 and T3, that showed lower pH between 4-6 h of fermentation.

Fig. 1. pH variation with fermentation time of three formulations of yogurt-like products, lupine-based.

T1= (90.7 % milk-like, 1 % Arracacia xanthorrhiza starch, 8 % saccharose, 0.3 % Danisco starter), T2= (89.7 % milk-like, 2 % Arracacia xanthorrhiza starch, 8 % saccharose, 0.3 % Danisco starter) and T3 = (88.7 % milk-like Arracacia xanthorrhiza starch, 8 % saccharose, 0.3 % Danisco starter).

Fig. 2. Titratable acidity variation with fermentation time of three formulations of yogurt-like products, lupine-based.

T1= (90.7 % milk-like, 1 % Arracacia xanthorrhiza starch, 8 % saccharose, 0.3 % Danisco starter), T2= (89.7 % milk-like, 2 % Arracacia xanthorrhiza starch, 8% saccharose, 0.3 % Danisco starter) and T3 = (88.7 % milk-like, 3 Arracacia xanthorrhiza starch, 8 % saccharose, 0.3 % Danisco starter).

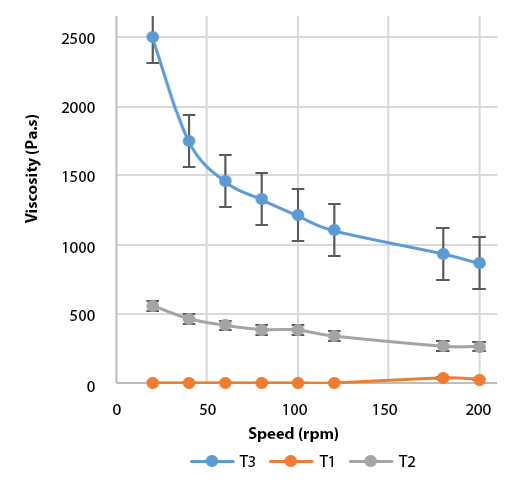

D. Rheological Analysis

The results showed that the flow behavior index was less than 1.00, corresponding to non-Newtonian fluid with pseudoplastic behavior, characterized by variations in its viscosity as a function of the shear rate [37] (Table II).

The consistency coefficient (K) in fluid rheology is a parameter of the power law model (Ostwald-de Waele model) that describes the behavior of non-Newtonian fluids [35]. The (k) value experienced an increased as the content of Arracacia starch in the formulation increased, which suggests that (K) depends on the chemical composition and molecular structure of the yogurt-like product. These results agree with those reported by [37], when observed that the consistency coefficient (k) increased with the banana powder content in soy yogurt, attributing this trend to the effect of total soluble solids. [38], after analyzing 270 yogurt samples, concluded that the addition of starch increased the consistency coefficient and the character pseudoplastic behavior of these products.

TABLE II. FLOW BEHAVIOR INDEX AND CONSISTENCY COEFFICIENT* OF THREE FORMULATIONS OF YOGURT-LIKE PRODUCTS, LUPINE-BASED

|

Formulation |

Consistency coefficient (k) (Pa.sn) |

Flow behavior index (n) |

Correlation coefficient |

|

T1 |

1059.97 |

-2.11 |

1 |

|

T2 |

1414.82 |

0.68 |

0.999 |

|

T3 |

199.05 |

0.56 |

0.998 |

|

|

|

|

|

*According to Waele’s Ostwald power law model. T1= (90.7 % milk-like, 1 % Arracacia xanthorrhiza starch, 8 % saccharose, 0.3 % Danisco strain), T2= (89.7 % milk-like, 2 % Arracacia xanthorrhiza starch, 8% saccharose, 0.3 % Danisco strain) and T3 = (88.7 % milk-like, 3 Arracacia xanthorrhiza starch, 8 % saccharose, 0.3 % Danisco strain).

As observed in Figure 3, the apparent viscosity was significantly higher (p ≤ 0.05) in the yogurt-like product with 3 % starch and lower in the formulation with 1 % Arracacia starch. This behavior is due to the increase in solids, which could have generated more interactions between particles and molecules, increasing resistance to flow and viscosity. Additionally, as the proportion of starch increases, its capacity for hydration too increases. In this manner, the gelatinized starch contributes to the formation of a denser and more stable matrix, enhancing consistency, reducing phase separation, and increasing the viscosity of the product [39]. It was also observed that increasing shear stress (η), the viscosity of yogurt-like products decreased, which is characteristic of systems with pseudoplastic behavior. In this regard, [40] demonstrated that carrot and Jerusalem artichoke flour, despite its low protein content and high fructose oligosaccharide content, generated a gel with high viscosity. However, it was lower than that obtained with the addition of buckwheat powder, which had a higher protein content.

Fig. 3. Viscosity variation with shear rate of three formulations of yogurt-like products, lupin-based.

T1= (90.7 % milk-like, 1% Arracacia xanthorrhiza starch, 8 % saccharose, 0.3 % Danisco starter), T2= (89.7 % milk-like, 2 % Arracacia xanthorrhiza starch, 8% saccharose, 0.3 % Danisco starter) and T3 = (88.7 % milk-like, 3 % Arracacia xanthorrhiza starch, 8 % saccharose, 0.3 % Danisco strain).

E. Microbiological Analysis

During the fermentation process, microorganisms that impair the quality of the yogurt-like products can grow [41]. To ensure that their count was within the permissible limits for consumption, a microbiological analysis was performed, and the results were shown in Table III. These were compared with the [27], which specifies the maximum concentrations of pathogenic microorganisms such as E. coli, as well as the minimum content of lactic acid bacteria cultures.

The concentrations of total coliforms, E. coli, molds, and yeasts from yogurt-like products did not exceed the permissible levels established by the INEN standard. The low concentration of undesirable microorganisms showed proper sterilization of the materials used to yogurt-like, lupine-based processing and monitoring at each stage of its production. Furthermore, lupin possesses antimicrobial activity, inhibiting E. coli strains; this capacity could have contributed to achieving the standards established by the INEN [42].

Changes in L. bulgaricus and S. thermophilus amounts in the yogurt-like formulations obtained from lupine milk are given in Table III. In the production of non-dairy yogurt-like products from lupine milk, the relationship between the addition of Arracacia starch and the growth of starter cultures was found to be significant (p ≤ 0.05). The sample with 1 % Arracacia starch showed a minimal lactic acid bacteria count. In contrast, the samples with 2 and 3 % Arracacia starch showed an increased growth and higher activity of starter. [43] reported that a lactic acid bacteria count between 107-108 ensures the conversion of sugars into lactic acid, lowering of pH, causing protein coagulation, development of flavor, aroma and beneficial probiotic effects for intestinal health; this favors the preservation of yogurt by inhibiting unwanted microbial growth.

TABLE III. MICROBIOLOGICAL COUNT OF THREE FORMULATIONS OF YOGURT-LIKE PRODUCTS, LUPIN-BASED

|

T1 |

T2 |

T3 |

|

|

Microorganisms |

UFC/g |

||

|

Total coliforms |

10 |

<10 |

<10 |

|

Echerichia Coli |

<1 |

<1 |

<1 |

|

Molds and yeasts |

100 |

67 |

133 |

|

Lactic acid bacteria |

7.9x107 |

4.0x108 |

1.8x108 |

|

|

|

|

|

T1= (90.7 % milk-like, 1% Arracacia xanthorrhiza starch, 8 % saccharose, 0.3 % Danisco strain), T2= (89.7 % milk-like, 2 % Arracacia xanthorrhiza starch, 8 % saccharose, 0.3 % Danisco strain) and T3 = (88.7 % milk-like, 3 % Arracacia xanthorrhiza starch, 8 % saccharose, 0.3 % Danisco strain).

F. Sensory acceptability analysis

Formulation T3 showed the highest scores in the key attributes color, taste, texture and acceptability, consolidating its position as the consumers’ favorite. The higher score in the attribute “acceptability” is relevant because it defines the acceptance or rejection of novel functional foods, since low acceptability can discourage purchase intention [44]. No significant difference was found in the odor attribute, which showed the lowest score (4.93/9.00), suggesting a lower production of aromatic compounds that contribute complexity to the sensory profile with respect to the other sensory attributes. This result could be related to the chemical composition of lupine milk, with a predominance of globular proteins, glutamic acid and aspartic acid [45].

IV. CONCLUSION

The results of the proximate analysis showed a favorable nutritional profile, with adequate protein, crude fiber and phenolic compound, comparable to other fermented plant-based products. The formulation with the highest percentage of Arracacia starch (T3) showed the mayor rheological stability and viscosity, suggesting that this ingredient not only contributes to texture but may also influence the preservation of yogurt’s functional benefits. Microbiological analyses confirmed the presence of lactic acid bacteria at an adequate count, which guarantees the probiotic function of the yogurt for intestinal health.

Sensory analysis showed that (T3) was the best rated by consumers in the attributes and acceptability. This demonstrates the potential of this formulation as an innovative alternative in the yogurt-like, lupine-based range. Consequently, future research could focus on smell optimization and shelf-life analysis for large-scale commercialization.

Notas

* Corresponding autor: monserrath.vasquez9366@utc.edu.ec

1. Monserrath Carolina Vásquez Rodríguez is with Universidad Técnica de Cotopaxi, Latacunga, Ecuador P.O. Box 050103, Latacunga, Ecuador. E-mail: monserrath.vasquez9366@utc.edu.ec, ORCID number https://orcid.org/0009-0001-6306-5069

2. Clara Elena Villacrés Poveda is with Instituto Nacional de Investigaciones Agropecuarias, INIAP, Quito, Ecuador INIAP, P.O. Box 17 0518, Mejía, Ecuador. E-mail: elena.villacres@iniap.gob.ec, ORCID number https://orcid.org/0000-0001-9660-5845

3. María Monserrath Morales-Padilla is with Unidad Académica de Posgrado, Universidad Técnica de Cotopaxi, Latacunga - Ecuador P.O. Box 050103, Latacunga, Ecuador. E-mail: maria.morales1144@utc.edu.ec, ORCID number https://orcid.org/0000-0001-9048-1538

4. Josué David Cruz Vasquez is with Universidad Técnica de Ambato, Ambato, Ecuador. E-mail: jcruz9670@uta.edu.ec, ORCID number https://orcid.org/0009-0000-4687-852X

REFERENCES

[1] M. Soumya, A. Suresh, R. Parameswaran and K. M. Nampoothiri, “Physico-chemical and organoleptic evaluation of probiotic plant-milk yogurt-type beverages as a functional alternative to dairy yogurts,” Biocatal Agric Biotechnol, vol. 57, no. 103060, p. 103060, 2024. https://doi.org/10.1016/J.BCAB.2024.103060

[2] V. R. Narala, M. A. Jugbarde, I. Orlovs and M. Masin, “Inulin as a prebiotic for the growth of vegan yoghurt culture in pea protein-based vegan yoghurt-ice cream, while improving the textural properties,” Applied Food Research, vol. 2, no. 2, p. 100136, 2022. https://doi.org/10.1016/J.AFRES.2022.100136

[3] D. Dhakal, G. Kumar, L. Devkota, D. Subedi and S. Dhital, “The choice of probiotics affects the rheological, structural, and sensory attributes of lupin-oat-based yoghurt,” Food Hydrocoll, vol. 156, no. 5, p. 110353, 2024. https://doi.org/10.1016/J.FOODHYD.2024.110353

[4] D. Dhakal, T. Younas, R. Bhusal, L. Devkota, L. Li, B. Zhang and S. Dhital, “The effect of probiotic strains on the proteolytic activity and peptide profiles of lupin oat-based yoghurt,” Food Hydrocoll, vol. 149, no. 1, p. 109570, 2024. https://doi.org/10.1016/J.FOODHYD.2023.109570

[5] S. A. Ahmed, W. A. Helmy and O. A. Ibrahim, “Evaluation of lupine seeds (Lupinus albus L.) neutral extract as a texture improver in low-fat yogurt production,” Int J Biol Macromol, vol. 263, no. 13, p. 130303, 2024. https://doi.org/10.1016/J.IJBIOMAC.2024.130303

[6] L. Hanley, S. Dobson and A. G. Marangoni, “Legume milk-based yogurt mimetics structured using glucono-δ-lactone,” Food Research International, vol. 184, no. 10, p. 114259, 2024. https://doi.org/10.1016/J.FOODRES.2024.114259

[7] J. Ran, S. Pang, H. Li, R. Zhao, Y. Li and M. Yang, “Gel properties of mung bean protein-sodium caseinate hybrid yogurt: Physicochemical properties, microstructure, and intermolecular interactions,” Food Chem X, vol. 24, no. 77, p. 101977, 2024. https://doi.org/10.1016/J.FOCHX.2024.101977

[8] T. Pantoa, K. Wadeesirisak, S. Saah and P. Saithong, “In vitro protein digestibility and bioactive activities of yogurt from black soybean (Glycine max L.) milk,” Future Foods, vol. 11, no. 36, p. 100636, 2025. https://doi.org/10.1016/J.FUFO.2025.100636

[9] Y. Ma, S. H. Lee, M. Guk, S. Cho and Y. Kim, “Enhancing soy yogurt texture and functionality with mealworm protein,” Journal of Food Composition and Analysis, vol. 141, no. 10, p. 107337, 2025. https://doi.org/10.1016/J.JFCA.2025.107337

[10] M. Caponio et al., “Development, optimization and integrated characterization of rice-based yogurt alternatives enriched with roasted and non-roasted sprouted barley flour,” Curr Res Food Sci, vol. 10, no. 1, p. 101059, 2025. https://doi.org/10.1016/J.CRFS.2025.101059

[11] X. Wang, L. Wang, X. Wei, C. Xu, G. Cavender, W. Lin and S. Sun, “Invited review: Advances in yogurt development Microbiological safety, quality, functionality, sensory evaluation, and consumer perceptions across different dairy and plant-based alternative sources,” J Dairy Sci, vol. 108, no. 1, pp. 33-58, 2025. https://doi.org/10.3168/JDS.2024-25322

[12] A. Zeinatulina, K. Tanilas, K. Ehala-Aleksejev, E. Viiard and T. Kriščiunaite, “Digestibility of protein and estimated bioavailability of mineral compounds in plant-based yoghurt alternatives,” Future Foods, vol. 11, no. 1, p. 100545, 2025. https://doi.org/10.3168/JDS.2024-2532210.1016/J.FUFO.2025.100545

[13] N. C. Jamanca, R. W. Ocrospoma, Y. M. Eguilas, R. A. Padilla and R. J. Silva, “Food grain quality: Analysis of physical, biometric, and colorimetric properties to promote consumption,” Heliyon, vol. 10, no. 7, p. e29234, 2024. https://doi.org/10.1016/J.HELIYON.2024.E29234

[14] A. Gulisano, S. Alves, J. N. Martins and L. M. Trindade, “Genetics and Breeding of Lupinus mutabilis: An Emerging Protein Crop,” Front Plant Sci, vol. 10, no. 1, p. 1385, 2019. https://doi.org/ 10.3389/FPLS.2019.01385

[15] FAO, “Simposio Regional del chocho o tarwi (Lupinus mutabilis),” Organización de las Naciones Unidas para la Alimentación y la Agricultura, 2016. Accessed: Jun. 27, 2024. [Online]. Available: https://www.fao.org/ecuador/noticias/detail-events/en/c/453499/

[16] L. Devkota, K. Kyriakopoulou, R. Bergia and S. Dhital, “Structural and Thermal Characterization of Protein Isolates from Australian Lupin Varieties as Affected by Processing Conditions,” Foods, vol. 12, no. 5, p. 908, 2023. https://doi.org/10.3390/foods12050908

[17] J. Yang and L. M. C. Sagis, “Interfacial behavior of plant proteins — novel sources and extraction methods,” Curr Opin Colloid Interface Sci, vol. 56, no. 1, p. 101499, 2021. https://doi.org/10.1016/J.COCIS.2021.101499

[18] A. Hickisch, R. Beer, R. F. Vogel and S. Toelstede, “Influence of lupin-based milk alternative heat treatment and exopolysaccharide-producing lactic acid bacteria on the physical characteristics of lupin-based yogurt alternatives,” Food Research International, vol. 84, no. 1, pp. 180-188, 2016. https://doi.org/10.1016/J.FOODRES.2016.03.037

[19] E. Villacrés, P. Cueva, M. Díaz, and C. M. Rosell, “Replacing Wheat Flour with Debittered and Fermented Lupin: Effects on Bread’s Physical and Nutritional Features,” Plant Foods for Human Nutrition, vol. 75, no. 4, pp. 569-575, 2020. https://doi.org/10.1007/S11130-020-00844-W/METRICS

[20] G. E. Sedó Molina, R. Shetty, C. Jacobsen, L. Duedahl-Olesen, E. B. Hansen and C. H. Bang-Berthelsen, “Synergistic effect of the coculture of Leuconostoc pseudomesenteroides and Lactococcus lactis, isolated from honeybees, on the generation of plant-based dairy alternatives based on soy, pea, oat, and potato drinks,” Food Microbiol, vol. 118, no. 3, pp. 104427, 2024. https://doi.org/10.1016/J.FM.2023.104427

[21] AOAC, “Official methods of analysis,” Current througn, no. 3, pp. 4-5, 2005. Accessed: Mar. 17, 2025. Available: https://www.academia.edu/43245633/Of_fi_cial_Methods_of_Anal_y_sis_of_AOAC_IN_TER_NA_TIONAL_18th_Edi_tion_2005

[22] Y. Deng, Y. Wang, G. Zhong and X. Yu, “Simultaneous quantitative analysis of protein, carbohydrate and fat in nutritionally complete formulas of medical foods by near-infrared spectroscopy,” Infrared Phys Technol, vol. 93, no. 2, pp. 124-129, 2018. https://doi.org/10.1016/J.INFRARED.2018.07.027

[23] M. Quiñones, M. Miguel and A. Aleixandre, “Los polifenoles, compuestos de origen natural con efectos saludables sobre el sistema cardiovascular,” Nutr Hosp, vol. 27, no. 1, pp. 76-89, 2012. Available: https://scielo.isciii.es/scielo.php?script=sci_abstract&pid=S0212-1611201 2000100009

[24] AOAC, “Official Methods of Analysis,” Association of Official Analytical, no. 15, 1990, Accessed: Mar. 17, 2025. [Online]. Available: https://law.resource.org/pub/us/cfr/ibr/002/aoac.methods.1.1990.pdf

[25] M. J. G. Salgado et al., “Impact of fiber-rich donkey milk yogurt on apparent viscosity and sensory acceptance,” LWT, vol. 145, no. 1, pp. 111494, 2021. https://doi.org/10.1016/J.LWT.2021.111494

[26] I. Ocaña, “Caracterización fisicoquímica, nutricional y reológica de cultivos andinos infrautilizados” [Tesis de Grado, Universidad Técnica de Ambato],” Universidad Técnica de Ambato, Tungurahua, Ambato, 2019.

[27] INEN 2395, “Leche Fermentadas,” Norma Técnica Ecuatoriana , no. 07, 2011, Accessed: Jan. 23, 2025. [Online]. Available: https://es.scribd.com/document/409014254/Leche-Yogurt

[28] M. Cuadros, “Atributos Sensoriales,” SCRIBD, 2018, Accessed: Apr. 20, 2022. [Online]. Available: https://es.scribd.com/document/160682506/ATRIBUTOS-SENSORIALES#fullscreen&from_embed

[29] L. Taramona-Ruiz, V. Quispe-Wong and M. Huatuco-Lozano, “Evaluación sensorial de un salami con extracto de un colorante en base de Ayrampo (Opuntia soehrensii),” Revista de Investigaciones de la Universidad Le Cordon Bleu, vol. 11, no. 1, pp. 17-29, 2024. https://doi.org/10.36955/RIULCB.2024V11N1.002

[30] F. Afiati, G. Priadi and F. Setiyoningrum, “The improvement of functional food in yogurt enriched with purple sweet potato (Ipomea batatas var. Ayamurasaki),” J Indones Trop Anim Agric, vol. 43, no. 2, pp. 159-168, 2018. https://doi.org/10.14710/JITAA.43.2.159-168

[31] T. Pramanik, M. A. R. Mazumder, J. F. Jany, S. I. Akash, A. Rahman and M. K. H. Bhuiyan, “Functional yogurt: An approach to fortify yogurt by polyphenols extracted from Bengal currant,” Applied Food Research, vol. 5, no. 1, pp. 100715, 2025. https://doi.org/10.1016/J.AFRES.2025.100715

[32] Y. Feng, L. Niu, D. Li, Z. Zeng, C. Sun, and J. Xiao, “Effect of calcium alginate/collagen hydrolysates beads encapsulating high-content tea polyphenols on quality characteristics of set yogurt during cold storage,” LWT, vol. 191, no. 1, pp. 115608, 2024. https://doi.org/10.1016/J.LWT.2023.115608.

[33] R. Qadir, W. N. A. Wan Mohamad Nasir, A. B. Azmi, S. Fatima, N. Mehmood, and A. S. Meor Hussin, “An insight into plant-based yogurts: Physicochemical, organoleptic properties and functional food aspects,” Journal of Food Composition and Analysis, vol. 143, no. 1, p. 107578, 2025. https://doi.org/10.1016/J.JFCA.2025.107578.

[34] S. Priatni, A. F. Devi, L. B. S. Kardono, and V. Jayasena, “QUALITY AND SENSORY EVALUATIONS OF TEMPE PREPARED FROM VARIOUS PARTICLE SIZES OF LUPIN BEANS [Evaluasi Sensorik dan Kualitas Tempe dari Kacang Lupin Berbagai Ukuran Partikel],” Jurnal Teknologi dan Industri Pangan, vol. 24, no. 2, pp. 209–209, 2013. https://doi.org/10.6066/JTIP.2013.24.2.209.

[35] E. Villacrés and C. M. Rosell, “Kinetics of solid-state fermentation of lupin with Rhizophus oligosporus based on nitrogen compounds balance,” Food Biosci, vol. 42, no.1, pp. 101118, 2021. https://doi.org/10.1016/J.FBIO.2021.101118.

[36] A. Chawafambira and T. Z. Jombo, “The effect of herbal Lippia javanica extracts on the bioactive content, functional properties, and sensorial profile of biofortified-orange maize based fermented maheu,” Applied Food Research, vol. 4, no. 1, pp. 100367, 2024. https://doi.org/10.1016/J.AFRES.2023.100367.

[37] V. Vicent, “Influence of banana powder on proximate composition, physicochemical and rheological properties of soy yoghurt,” Applied Food Research, vol. 4, no. 2, pp. 100450, 2024. https://doi.org/10.1016/J.AFRES.2024.100450.

[38] I. Bourouis, D. J. McClements, C. Chen, H. Li, Z. Pang, and X. Liu, “Formulations and evaluations of structural and physico-chemical properties of soy yogurts: Effect of incorporating soy protein isolate/chitosan complexed microgels,” LWT, vol. 206, no. 1, pp. 116569, 2024. https://doi.org/10.1016/J.LWT.2024.116569

[39] Z. Pang, R. Xu, T. Luo, X. Che, N. Bansal and X. Liu, “Physiochemical properties of modified starch under yogurt manufacturing conditions and its relation to the properties of yogurt,” J Food Eng, vol. 245, no1, pp. 11-17, 2019. https://doi.org/10.1016/J.JFOODENG.2018.10.003

[40] R. Dong et al., “Enrichment of yogurt with carrot soluble dietary fiber prepared by three physical modified treatments: Microstructure, rheology and storage stability,” Innovative Food Science & Emerging Technologies, vol. 75, pp. 102901, 2022. https://doi.org/ 10.1016/J.IFSET.2021.102901

[41] J. Arriaga and J. Gonzalo, “Control de calidad fisicoquímica, microbiológica y probiótica de yogurt artesanal de mercados de los distritos de Santiago y Cusco, 2023,” Universidad Nacional San Antonio, 2024. Accessed: Feb. 06, 2025. [Online]. Available: https://repositorio.unsaac.edu.pe/handle/20.500.12918/8521

[42] K. Poma Zanabria and F. Y. Rojas Calderón, “Actividad antibacteriana in vitro del extracto etanólico de semillas de Lupinus mutabilis sweet (Tarwi) frente A Escherichia Coli ATCC 25922,” Universidad María Auxiliadora, 2023. Accessed: Feb. 21, 2025. [Online]. Available: https://repositorio.uma.edu.pe/bitstream/handle/20.500.12970/1665/TESIS%20POMA-ROJAS.pdf?sequence=1

[43] M. Cerna, “Uso de bebidas vegetales de Chocho (Lupinus mutabilis), Garbanzo (Cicer arietinum) y Amaranto (Amaranthus) como sustitución de la leche de vaca en yogurt.,” Universidad Técnica de Babahoyo, 2024. Accessed: Feb. 21, 2025. [Online]. Available: http://dspace.utb.edu.ec/handle/49000/16060

[44] J. Zhang, A. Perez-Gavilan and A. C. Neves, “Fortification of dairy-free yoghurt with bioactive protein from solid-state fermented brewers’ spent grain,” Applied Food Research, vol. 5, no. 1, pp. 100833, 2025. https://doi.org/10.1016/J.AFRES.2025.100833

[45] E. Villacrés, M. B. Quelal, X. Jácome, G. Cueva and C. M. Rosell, “Effect of debittering and solid-state fermentation processes on the nutritional content of lupine (Lupinus mutabilis Sweet),” Int J Food Sci Technol, vol. 55, no. 6, pp. 2589-2598, 2020. https://doi.org/10.1111/IJFS.14512